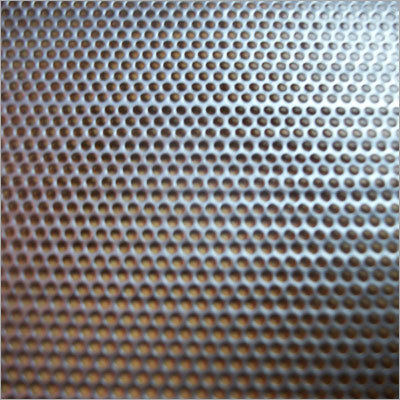

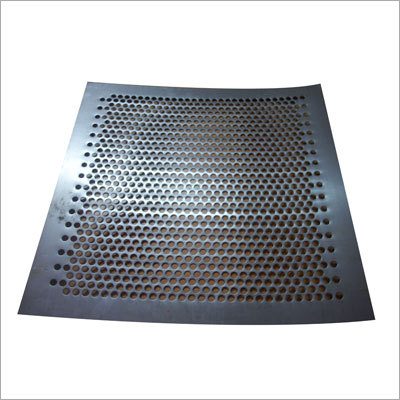

Metal Perforated Sheets

Metal Perforated Sheets Specification

- Shape

- Rectangular, Square, Round, Customized

- Process

- Punching, Perforation, Shearing, Cutting

- Temper

- Hard, Soft

- Standard

- ASTM, IS, DIN

- Surface Treatment

- Polished, Galvanized, Powder Coated

- Material

- Mild Steel, Stainless Steel, Galvanized Steel, Aluminum

- Type

- Perforated Sheet

- Technique

- Perforated, Punched, CNC

- Thickness

- 0.5 mm to 8 mm

- Application

- Industrial, Architectural, Security Fencing, Filtration, Ventilation, Decorative

- Feature

- Corrosion Resistant, Durable, High Tensile Strength, Fine Finish

About Metal Perforated Sheets

Metal Perforated Sheets

We provide metal perforated sheets that are used in various types of filter industries, furniture, diesel generator canopies and various applications. This product has found its place in many industries and has been put to variety of uses. Our clients from different domain like Food Industry, Automobiles, Engineering Industries, Electronics, Agricultural Tools, etc., has been buying this product from us.

Multi-Purpose Performance

Designed for high performance across various sectors, metal perforated sheets fulfill roles in industrial machinery, architectural facades, security fencing, filtration systems, and ventilation grilles. Their robust construction and range of materials provide optimal durability and adaptability for challenging environments.

Advanced Manufacturing Processes

Utilizing methods such as CNC perforation, punching, and precise cutting, these sheets are customizable in terms of shape, hole pattern, and sheet size. The combination of advanced fabrication and stringent quality standards ensures that every sheet meets critical performance needs.

FAQs of Metal Perforated Sheets:

Q: How are metal perforated sheets manufactured to ensure precision and durability?

A: Metal perforated sheets are fabricated using processes like punching and CNC perforation, which allow for accurate pattern creation and consistent thickness. Stringent manufacturing techniques, along with quality materials, provide enhanced tensile strength and resistance to wear.Q: What types of materials are available for these perforated sheets?

A: Perforated sheets are available in mild steel, stainless steel, galvanized steel, aluminum, and other specialized metals. This diversity of materials allows users to choose sheets with the right balance of corrosion resistance, mechanical strength, and aesthetic appeal for their application.Q: When is it beneficial to select a corrosion-resistant finish on perforated sheets?

A: Opting for a corrosion-resistant finish, such as galvanization or powder coating, is beneficial in environments exposed to moisture, chemicals, or changing weather conditions. Such finishes extend the service life and preserve the sheets structural integrity.Q: Where can these metal perforated sheets be used effectively?

A: They are widely used in industrial settings for filtration and ventilation, architectural projects for facades and ceilings, security installations like fencing, and decorative applications in both commercial and residential spaces.Q: What are the benefits of using perforated sheets in architectural and industrial applications?

A: These sheets provide superior strength-to-weight ratios, efficient airflow or filtration, aesthetic enhancements, and vandal resistance. Their adaptability in shape, finish, and size offers tailored solutions for diverse project requirements.Q: How should the appropriate perforated sheet thickness be selected?

A: Selecting thickness between 0.5 mm to 8 mm depends on required structural load, intended use (such as heavy-duty filtration or decorative panels), and installation environment. Manufacturers can guide the optimal thickness for specific applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheets Category

Perforated Sheets

Minimum Order Quantity : 100 Kilograms

Technique : Hot Rolled

Material : Stainless Steel

Feature : High Quality

Surface Treatment : Galvanized

Usage : Industrial

Heavy Metal Perforated Sheets

Technique : Other, Cold Rolled, Hot Rolled, Punching, Perforation

Material : Other , Mild Steel, Stainless Steel, Galvanized Iron, Aluminium

Feature : High strength, durability, corrosion resistance

Surface Treatment : Other , Galvanized, Powder Coated, Polished, Painted

Send Inquiry

Send Inquiry