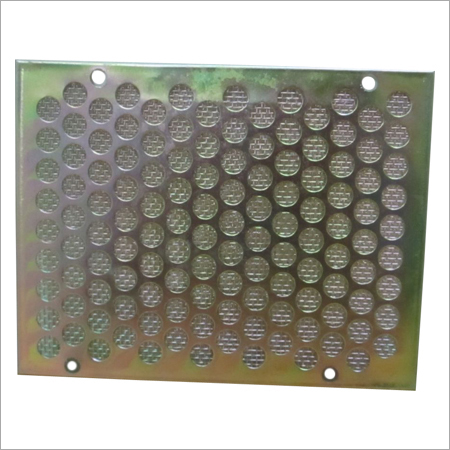

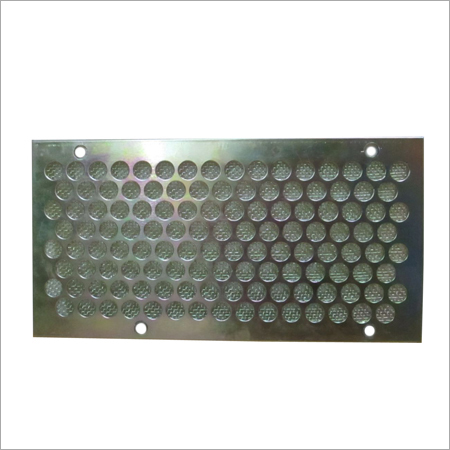

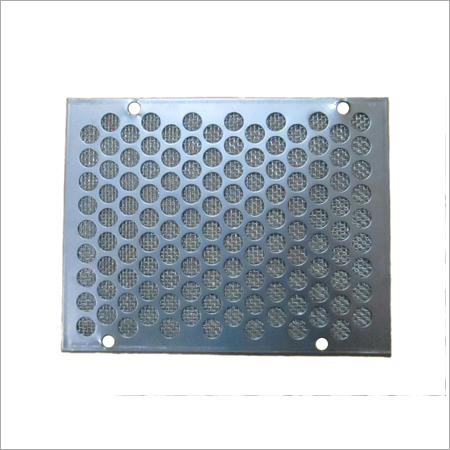

Guard Filter Equipment

Guard Filter Equipment Specification

- Process

- Cutting, shaping, welding, polishing

- Standard

- IS/ASTM/DIN/EN

- Surface Treatment

- Polished, anti-corrosive coated

- Temper

- Customizable as per requirement

- Shape

- Cylindrical

- Material

- Stainless Steel

- Type

- Guard Filter Equipment

- Technique

- Welded and perforated

- Thickness

- 3-10 mm

- Application

- Industrial filtration systems, water treatment plants, chemical processing, oil & gas industries, power plants

- Feature

- High filtration efficiency, corrosion-resistant, durable, easy installation, low maintenance

- Pressure Resistance

- Up to 25 bar

- Mounting Type

- Vertical/Horizontal

- End Connections

- Flanged, threaded

- Operating Temperature Range

- -20°C to 200°C

- Weight

- Varies by model, typically 10-50 kg

- Flow Capacity

- Up to 1000 m3/h

- Filtration Rating

- 10-200 microns

- Mesh Size

- Customized

- Color

- Silver/Metallic

About Guard Filter Equipment

Our organization has successfully expanded its business in market by manufacturing and supplying Guard Filter Equipment. This equipment is used in agricultural, chemical, petrochemical and cement industry. To manufacture this equipment, we use finest quality stainless steel. The size and finishing of this equipment can be customized as per the requirements of clients. We offer this Guard Filter Equipment at pocket friendly prices to clients.

Features:

- Sturdy and durable

- Resistant to rust

- Smooth finishing

Superior Filtration Performance

Engineered to provide a high level of filtration efficiency, our Guard Filter Equipment ensures thorough removal of particulates ranging from 10 to 200 microns. Its robust stainless steel construction, in conjunction with precision-welded and perforated mesh, delivers consistent results even under demanding industrial conditions.

Versatile and Reliable

Designed for adaptability, the equipment supports both vertical and horizontal installation. Its corrosion-resistant finish and durable build, conforming to global standards such as IS, ASTM, DIN, and EN, make it suitable for various environments including water treatment, power plants, and chemical processing industries.

Easy Installation and Maintenance

Ease of integration is achieved through flanged or threaded connections, and the equipments structure allows for straightforward cleaning and minimal upkeep. Its low maintenance needs reduce downtime, contributing to operational efficiency and long-term value.

FAQs of Guard Filter Equipment :

Q: How is the Guard Filter Equipment installed in industrial filtration systems?

A: The Guard Filter Equipment can be installed either vertically or horizontally, using its flanged or threaded end connections. The installation process involves mounting the filter in the pipeline, ensuring proper alignment, and securely tightening the connections. Its design accommodates straightforward integration into existing systems.Q: What makes the Guard Filter Equipment suitable for corrosive and high-pressure environments?

A: Constructed from high-grade stainless steel and finished with polished or anti-corrosive coatings, the filter is highly resistant to corrosion and can withstand pressures up to 25 bar. This makes it ideal for harsh industrial settings such as chemical processing and oil & gas facilities.Q: When should mesh size customization be considered for this filter?

A: Mesh size customization is recommended when specific particle removal needs must be met, or when processing fluids with varying contamination profiles. Tailoring the mesh enables optimal filtration efficiency to meet unique operational requirements.Q: Where can the Guard Filter Equipment be used effectively?

A: This equipment is well-suited for use in industrial filtration systems, water treatment plants, power plants, oil & gas industries, and chemical processing facilities, providing reliable filtration and long service life across multiple sectors.Q: What is the process behind manufacturing this filtration equipment?

A: The manufacturing process involves cutting, shaping, welding, and perforating stainless steel according to standardized specifications (IS/ASTM/DIN/EN). The final product is polished or coated for anti-corrosive properties, and undergoes quality checks to ensure durability and efficiency.Q: How does using Guard Filter Equipment benefit industrial operations?

A: Benefits include enhanced filtration efficiency, reduced equipment maintenance, prolonged operational life, and minimized system downtime. Its corrosion-resistant, durable build ensures reliability, even under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

Screen Guard Filter

Surface Treatment : Other , Matte Finish

Shape : Rectangular

Type : Screen Guard Filter

Standard : ISO 9001:2015

Feature : Antiglare, Scratch Resistant, High Durability, Eye Protection

Thickness : 0.3 mm

SS Wire Mesh Circle

Surface Treatment : Other , Polished

Shape : Round

Type : Wire Mesh Circle

Standard : ASTM, JIS, DIN

Feature : Highly Durable, Corrosion Resistant, Fine Finish

Thickness : 0.4 mm 2 mm

Perforated Filter

Surface Treatment : Other , Galvanized, Polished, Powder Coated

Shape : Round, Rectangular, Custom shapes

Type : Perforated Filter

Standard : ASTM, DIN, ISO

Feature : High strength and durability, corrosion resistant, efficient filtration, easy to clean, customizable perforation sizes

Thickness : 0.5 mm to 3 mm

Industrial Screen Guard Filter

Surface Treatment : Other , Polished / Galvanized

Shape : Cylindrical, Round, or Customizable

Type : Guard Filter / Screen Guard

Standard : ASTM / IS / Custom

Feature : Corrosion Resistant, Durable, High Filtration Efficiency

Thickness : 0.8 mm 2 mm

Send Inquiry

Send Inquiry