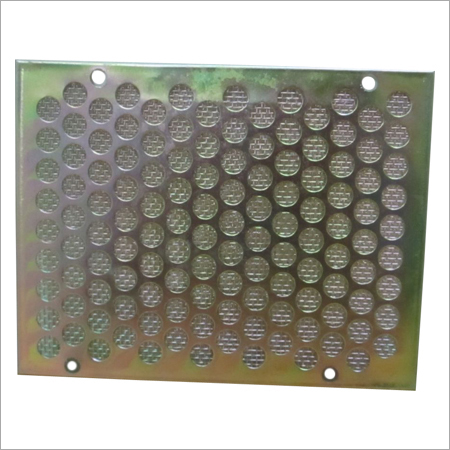

Perforated Filter

Perforated Filter Specification

- Standard

- ASTM, DIN, ISO

- Process

- Mechanical Perforation, Laser Cutting

- Shape

- Round, Rectangular, Custom shapes

- Surface Treatment

- Galvanized, Polished, Powder Coated

- Temper

- Annealed, Hardened

- Material

- Stainless Steel, Mild Steel, Aluminum

- Type

- Perforated Filter

- Technique

- Perforation

- Thickness

- 0.5 mm to 3 mm

- Application

- Industrial filtration, chemical processing, water treatment, oil & gas, pharmaceuticals, food processing

- Feature

- High strength and durability, corrosion resistant, efficient filtration, easy to clean, customizable perforation sizes

- Customization

- Available as per client drawings

- Width

- Up to 1500 mm

- Edge Finish

- Plain, Welded, Flanged

- Hole Pattern

- Round, Square, Slotted

- Open Area Percentage

- 20% to 60%

- Length

- Up to 2500 mm

- Operating Temperature

- -50°C to 400°C

- Color

- Silver, custom colors available on request

- Compatibility

- Suitable for liquids, gases, solids filtration

- Weight

- Varies based on dimension and material

- Hole Size

- 0.5 mm to 10 mm

About Perforated Filter

We have installed advanced machines in the production unit that enable us in manufacturing and supplying Perforated Filter. This filter is widely used in industrial filter tubes, textile machinery spares and dye tubes. We manufacture this filter under the firm guidance of expert supervisors using high quality materials, sourced from trusted vendors. Clients can avail this Perforated Filter from us in different sizes and specifications as per their requirements. We offer this filter at affordable prices.

Features:

- Light weight

- Easy to install

- Sturdy and durable

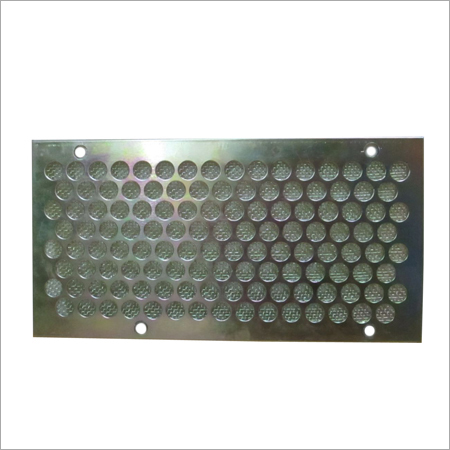

Premium Filtration for Every Industry

Our Perforated Filters are designed to meet the demanding needs of industries such as water treatment, oil & gas, pharmaceuticals, and food processing. With customizable hole patterns and sizes, they deliver efficient filtration for liquids, gases, and solids, ensuring dependable performance in complex environments.

Tailored to Your Requirements

We offer full customization on filter dimensions, shapes (round, rectangular, and custom), and finishes. Manufactured using mechanical perforation or laser cutting, each unit meets global standards like ASTM, DIN, and ISO. Choose from various materials and surface treatments for optimal compatibility and durability.

FAQs of Perforated Filter:

Q: How do I select the right perforated filter for my application?

A: To choose the optimal perforated filter, consider the substance you need to filter (liquids, gases, or solids), the desired open area percentage, required hole pattern and size, and operating temperature. We offer customization to match your specific needs and application, ensuring maximum efficiency.Q: What materials are available for the perforated filters, and how do I decide which to use?

A: Perforated filters are available in stainless steel, mild steel, aluminum, and other materials. Stainless steel suits corrosive environments and high durability requirements, while aluminum is lightweight and mild steel is cost-effective. We can help you select based on your applications environment and process.Q: When should I opt for a custom filter design rather than a standard option?

A: A custom filter is ideal if your application requires specific dimensions, unique hole patterns, or tailored edge finishes not covered by standard models. Send your drawings or requirements, and we will manufacture the filter to your precise specifications.Q: Where are perforated filters commonly used?

A: These filters are widely employed in industries such as water treatment, food processing, oil & gas, pharmaceuticals, and chemical processing due to their high strength, corrosion resistance, and adaptability to diverse filtration needs.Q: What process is used to manufacture these perforated filters?

A: We utilize mechanical perforation and laser cutting techniques to achieve precise hole sizes and patterns. Filters undergo additional surface treatments such as galvanizing, polishing, or powder coating for enhanced durability and performance.Q: How should I maintain and clean a perforated filter?

A: Perforated filters are designed for easy cleaning. Depending on the application and material, rinse with water or use suitable cleaning agents. Regular inspection and maintenance help extend filter life and ensure consistent performance.Q: What are the key benefits of using your perforated filters?

A: Our filters provide high durability, excellent corrosion resistance, efficient and customizable filtration, easy maintenance, and are available in a range of shapes, sizes, and finishes to best suit your operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

SS Wire Mesh Circle

Process : Punching

Thickness : 0.4 mm 2 mm

Surface Treatment : Other , Polished

Material : Stainless Steel

Shape : Round

Technique : Woven

Perforated Tube

Process : Cold Rolled, Hot Rolled

Thickness : 0.5 mm to 3 mm

Surface Treatment : Other , Polished, Galvanized

Material : Other , Stainless Steel, Mild Steel, Aluminium

Shape : Round

Technique : Other, Perforation, Welded

Screen Guard Filter

Process : Laser Cutting

Thickness : 0.3 mm

Surface Treatment : Other , Matte Finish

Material : Other , Polycarbonate

Shape : Rectangular

Technique : Other, Precision Cut

Industrial Screen Guard Filter

Process : Punching, Welding, Finishing

Thickness : 0.8 mm 2 mm

Surface Treatment : Other , Polished / Galvanized

Material : Stainless Steel

Shape : Cylindrical, Round, or Customizable

Technique : Other, Welded Mesh / Perforated

Send Inquiry

Send Inquiry