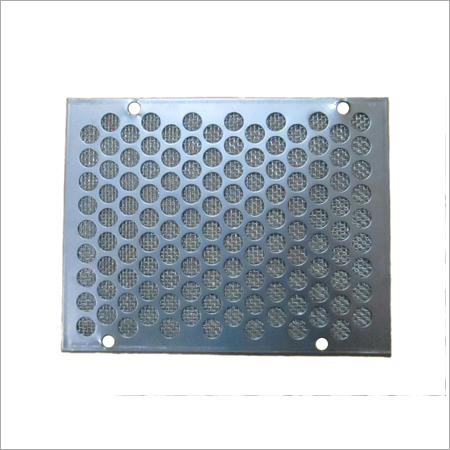

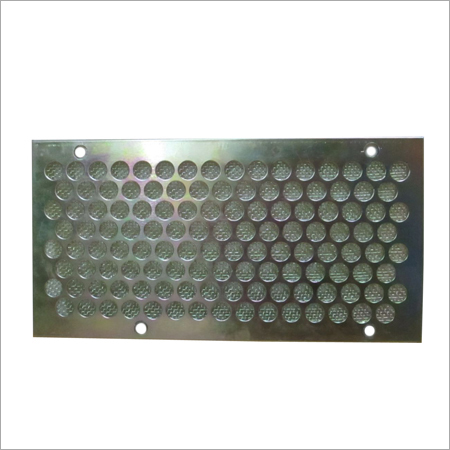

Industrial Screen Guard Filter

Industrial Screen Guard Filter Specification

- Standard

- ASTM / IS / Custom

- Temper

- Hard

- Shape

- Cylindrical, Round, or Customizable

- Surface Treatment

- Polished / Galvanized

- Process

- Punching, Welding, Finishing

- Material

- Stainless Steel

- Type

- Guard Filter / Screen Guard

- Technique

- Welded Mesh / Perforated

- Thickness

- 0.8 mm - 2 mm

- Application

- Industrial Filtration, Water Treatment, Chemical Processing

- Feature

- Corrosion Resistant, Durable, High Filtration Efficiency

- Temperature Resistance

- Up to 120°C

- End Connection

- Threaded/BSP

- Usage

- Reusable/Replaceable Element

- Height

- 150 mm to 1000 mm

- Color

- Silver

- Flow Rate

- Up to 100 m³/hr

- Mesh Size

- 60 to 300 micron

- Filtration Efficiency

- 99%

- Operating Pressure

- Up to 10 bar

- Diameter Range

- 50 mm to 450 mm

About Industrial Screen Guard Filter

We have marked a distinct position in the domain by manufacturing and supplying Industrial Screen Guard Filter. To manufacture this filter, our diligent manpower uses quality grade stainless steel. This filter is used in chemical and petrochemical industry. We can customize this filter for clients in different sizes and specifications as per their requirements. Moreover, we offer this Industrial Screen Guard Filter at pocket friendly prices to clients.

Features:

- Rust proof

- Resistant to bend

- Easy to install

Engineered for High-Performance Filtration

This industrial screen guard filter provides outstanding durability and corrosion resistance, making it an ideal choice for demanding industrial, chemical, and water treatment processes. Available in various diameters, heights, and micron ratings, it effectively captures particulate matter while maintaining a high flow rate and minimal pressure drop.

Versatile Design and Customization

Supplied in cylindrical, round, or custom shapes and constructed using ASTM/IS standards or tailored specifications, the filter adapts to your unique operational requirements. Its reusable or replaceable element structure maximizes convenience and cost-efficiency, making maintenance straightforward in a wide range of applications.

FAQs of Industrial Screen Guard Filter:

Q: How is the Industrial Screen Guard Filter installed and maintained?

A: The filter is installed directly into your system using threaded or BSP end connections. Maintenance is straightforward: simply remove the element for cleaning or replacement, depending on your needs. Its reusable design enables regular cleaning without loss of performance.Q: What benefits does using this screen guard filter offer in industrial applications?

A: It provides exceptional 99% filtration efficiency, corrosion resistance, and durability. Its stainless steel construction and high-quality welded mesh ensure long service life, reduce downtime, and support clean, uninterrupted operation in water treatment and chemical processing systems.Q: When should the filtration element be cleaned or replaced?

A: The element should be cleaned or replaced based on the level of particulate accumulation and pressure drop observed in your system. For optimal performance, establish a routine inspection schedule according to your specific process requirements.Q: Where can this filter be used effectively?

A: This screen guard filter is suited to a variety of environments, including industrial filtration systems, water treatment plants, and chemical processing lines. Its robust design and material make it compatible with harsh and demanding operational settings.Q: What is the filtration process employed by this product?

A: The filtration process utilizes welded mesh or perforated stainless steel to physically intercept particles sized between 60 and 300 microns, achieving a 99% filtration efficiency. Suspended solids are effectively separated, ensuring only clean fluids pass through.Q: How does the filters construction ensure durability and corrosion resistance?

A: Manufactured from high-grade stainless steel with polished or galvanized surface treatment, and fabricated using advanced punching and welding techniques, while adhering to ASTM/IS/custom standards, this filter can withstand high pressure, temperature variations, and corrosive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

Guard Filter Equipment

Surface Treatment : Other , Polished, anticorrosive coated

Feature : High filtration efficiency, corrosionresistant, durable, easy installation, low maintenance

Shape : Cylindrical

Process : Cutting, shaping, welding, polishing

Thickness : 310 mm

Application : Industrial filtration systems, water treatment plants, chemical processing, oil & gas industries, power plants

Perforated Tube filter

Surface Treatment : Other , Polished, Galvanized, Coated

Feature : Corrosion Resistance, High Durability, Fine Filtration, High Strength

Shape : Cylindrical, Round

Process : Punching, Forming, Fabrication

Thickness : 0.5 mm to 3 mm (customizable)

Application : Liquid Filtration, Air Filtration, Industrial Filters, Water Treatment Plants

SS Wire Mesh Circle

Surface Treatment : Other , Polished

Feature : Highly Durable, Corrosion Resistant, Fine Finish

Shape : Round

Process : Punching

Thickness : 0.4 mm 2 mm

Application : Filtration, Sieving, Industrial, Chemical, Food Processing

Perforated Filter

Surface Treatment : Other , Galvanized, Polished, Powder Coated

Feature : High strength and durability, corrosion resistant, efficient filtration, easy to clean, customizable perforation sizes

Shape : Round, Rectangular, Custom shapes

Process : Mechanical Perforation, Laser Cutting

Thickness : 0.5 mm to 3 mm

Application : Industrial filtration, chemical processing, water treatment, oil & gas, pharmaceuticals, food processing

Send Inquiry

Send Inquiry