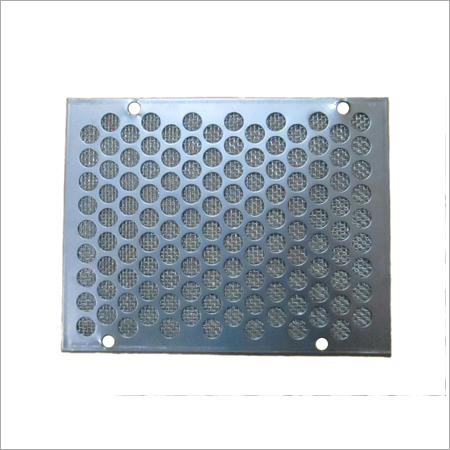

SS Wire Mesh Circle

SS Wire Mesh Circle Specification

- Standard

- ASTM, JIS, DIN

- Process

- Punching

- Temper

- Hard

- Surface Treatment

- Polished

- Shape

- Round

- Material

- Stainless Steel

- Type

- Wire Mesh Circle

- Technique

- Woven

- Thickness

- 0.4 mm - 2 mm

- Application

- Filtration, Sieving, Industrial, Chemical, Food Processing

- Feature

- Highly Durable, Corrosion Resistant, Fine Finish

- Mesh Size

- 10-200 Mesh

- Usage Temperature

- Up to 800°C

- Color

- Silver

- Customization

- Available in custom sizes

- Open Area

- 30% - 75%

- Pack Type

- Polybag or Carton

- Diameter

- 50 mm - 300 mm

- Edge Type

- Smooth

- Grade

- SS304 / SS316 / SS316L

About SS Wire Mesh Circle

We are holding rich experience in the domain of manufacturing and supplying SS Wire Mesh Circle. This circle is manufactured under the firm guidance of expert supervisors using high quality stainless steel. To provide protection from rust, this circle is coated with anti corrosive materials. We make available this circle for clients in different sizes and specification as per their requirements. Also, we offer this SS Wire Mesh Circle at market leading prices to clients.

Features:

- Resistant to bend

- Light weight

- Can withstand high impact

Precision-Engineered for Reliability

SS Wire Mesh Circles are manufactured using specialized woven techniques and precision punching. Each circle exhibits uniform mesh openings and smooth edges, ensuring consistent performance and safety across diverse environments. They are rigorously tested to meet international quality standards such as ASTM, JIS, and DIN, making them trusted by various industries.

Versatile Industrial Applications

These wire mesh circles are indispensable for filtration and sieving in industrial, chemical, and food processing settings. Their corrosion-resistant properties, coupled with resistance to high temperatures up to 800C, make them suitable for demanding environments, offering reliable long-term use. With open area options ranging from 30% to 75%, they accommodate different levels of permeability as required.

Customization and Easy Handling

We offer SS Wire Mesh Circles in a variety of diameters and thicknesses, with custom sizing available to meet specific requirements. Packed securely in polybags or cartons, they are designed for straightforward handling, storage, and installation. Our team supports tailored solutions, catering to your unique project needs.

FAQs of SS Wire Mesh Circle:

Q: How are SS Wire Mesh Circles manufactured?

A: SS Wire Mesh Cirles are fabricated using woven stainless steel wire, followed by precise punching to achieve round shapes. They feature polished surfaces and smooth edges, ensuring a fine finish and structural integrity according to ASTM, JIS, and DIN standards.Q: What industries commonly use these wire mesh circles?

A: Industries such as filtration, chemical processing, food processing, and general industrial manufacturing rely on SS Wire Mesh Circles for sieving, separation, and filtration due to their robustness and high corrosion resistance.Q: When should I choose SS316 or SS316L grade over SS304?

A: SS316 and SS316L grades are recommended when superior corrosion resistance is required, particularly in aggressive chemical environments or for food-grade applications, whereas SS304 is ideal for general purposes.Q: Where can SS Wire Mesh Circles be installed?

A: These mesh circles can be installed in filtration units, sieving systems, industrial machinery, and chemical processing equipment. Their adaptability allows use both in factories and lab-scale setups.Q: What is the process for ordering custom sizes?

A: To order custom-sized wire mesh circles, provide the desired diameter, mesh size, thickness, and any specific requirements. Our manufacturing facility in India can accommodate various requests, delivering tailored solutions packed in polybags or cartons.Q: How do temperature and open area affect performance?

A: SS Wire Mesh Circles maintain high durability and efficiency at temperatures up to 800C. The selected open area (30%75%) influences flow rates and filtration precision, allowing customization for each application.Q: What benefits do these wire mesh circles offer over alternatives?

A: They feature outstanding corrosion resistance, fine finish, durability, and stable performance under high temperatures. Their smooth edges and customizability make them superior for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

Guard Filter Equipment

Feature : High filtration efficiency, corrosionresistant, durable, easy installation, low maintenance

Technique : Other, Welded and perforated

Standard : IS/ASTM/DIN/EN

Material : Stainless Steel

Temper : Customizable as per requirement

Process : Cutting, shaping, welding, polishing

Perforated Tube filter

Feature : Corrosion Resistance, High Durability, Fine Filtration, High Strength

Technique : Other, Perforation, Welding, Rolling

Standard : ASTM, DIN, ISO

Material : Other , Stainless Steel, Mild Steel, Galvanized Steel

Temper : As per customer requirement

Process : Punching, Forming, Fabrication

Perforated Tube

Feature : Corrosion Resistance, Durable, Fine Finish

Technique : Other, Perforation, Welded

Standard : ASTM, DIN, ISO

Material : Other , Stainless Steel, Mild Steel, Aluminium

Temper : Customizable

Process : Cold Rolled, Hot Rolled

Perforated Filter

Feature : High strength and durability, corrosion resistant, efficient filtration, easy to clean, customizable perforation sizes

Technique : Other, Perforation

Standard : ASTM, DIN, ISO

Material : Other , Stainless Steel, Mild Steel, Aluminum

Temper : Annealed, Hardened

Process : Mechanical Perforation, Laser Cutting

Send Inquiry

Send Inquiry