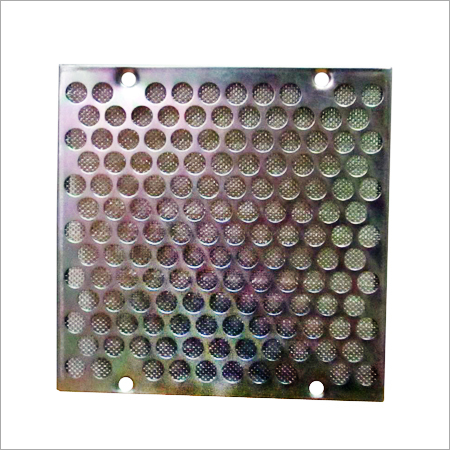

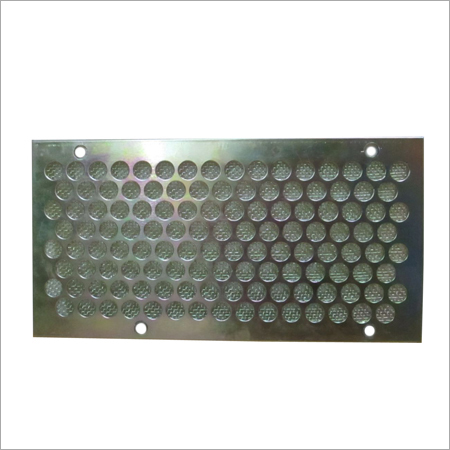

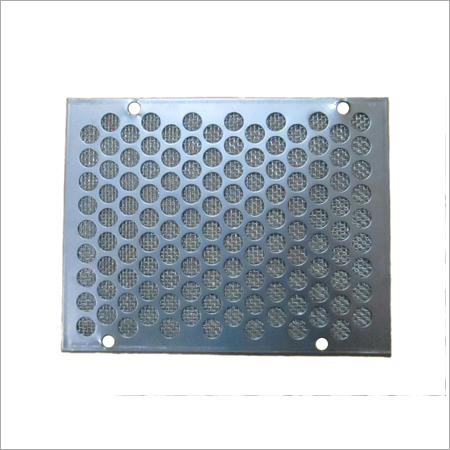

Perforated Tube

Perforated Tube Specification

- Surface Treatment

- Polished, Galvanized

- Process

- Cold Rolled, Hot Rolled

- Standard

- ASTM, DIN, ISO

- Shape

- Round

- Temper

- Customizable

- Material

- Stainless Steel, Mild Steel, Aluminium

- Type

- Perforated Tube

- Technique

- Perforation, Welded

- Thickness

- 0.5 mm to 3 mm

- Application

- Filtration, Exhaust Pipes, Oil and Gas, Agriculture, HVAC

- Feature

- Corrosion Resistance, Durable, Fine Finish

- Color

- Silver, Customized

- End Style

- Plain, Threaded, Flanged

- Packaging

- Bundle, Wooden Box, As required

- Length

- Up to 6 meters

- Customization

- Available as per requirement

- Open Area Percentage

- Up to 60%

- Hole Size

- 0.5 mm to 25 mm

- Hole Pattern

- Round, Square, Slot

- Outer Diameter

- 10 mm to 150 mm

- Operating Temperature

- -40°C to 400°C

About Perforated Tube

Our consistent efforts and dedication enable us to carve a niche as a most trustworthy manufacturer and supplier of Perforated Tube. This tube is extensively used in cement, chemical and agricultural industry. To manufacture this tube, our diligent workforce uses quality grade stainless steel and mild steel. Clients can avail this tube from us in different sizes and specifications as per their requirements. Moreover, we offer this Perforated Tube at market leading prices to clients.

Features:

- Easy to install

- Resistant to breakage

- Rugged construction

Versatile Applications Across Industries

Perforated tubes are integral to numerous industries including oil and gas, HVAC, agriculture, and filtration systems. Thanks to their customizable features and variety of shapes, sizes, and finishes, they enhance processes like particle separation and airflow regulation. Their corrosion-resistant properties and adaptable design make them a trusted choice for both industrial and commercial applications.

Customization and Quality Assurance

We provide perforated tubes tailored to your exact requirements, from dimensions and hole patterns to surface finish and end style. Meeting ASTM, DIN, and ISO standards, each tube undergoes meticulous inspection for durability, corrosion resistance, and fine finish, delivering both quality and flexibility in every order.

FAQs of Perforated Tube:

Q: How are perforated tubes manufactured to ensure durability and corrosion resistance?

A: Our perforated tubes are made using specialized perforation and welding techniques from materials like stainless steel, mild steel, and aluminium. Surface treatments such as polishing or galvanization increase durability and provide resistance to corrosion, making them suitable for demanding environments.Q: What customization options are available for perforated tubes?

A: You can specify dimensions, hole patterns (round, square, slot), hole size, open area percentage, thickness, end styles (plain, threaded, flanged), material, finish, and packaging. This ensures the perforated tube is suited precisely for your intended application.Q: When is a perforated tube with a higher open area percentage beneficial?

A: A higher open area percentage, up to 60%, is valuable when maximum fluid or air flow is needed, such as in filtration or exhaust applications. It enhances filtration efficiency or air passage while maintaining structural strength.Q: Where can perforated tubes be used most effectively?

A: Perforated tubes are especially effective in filtration systems, exhaust pipes, oil and gas installations, agricultural equipment, and HVAC systems. Their robust design and adaptability make them suitable for both industrial and commercial uses.Q: What is the typical process for ordering and delivering customized perforated tubes?

A: Simply provide your specifications for size, material, hole pattern, finish, and packaging. After technical review and confirmation, we manufacture and carefully package the tubesbundled or in wooden boxesdelivering them in accordance with your requirements.Q: What are the key benefits of using your perforated tubes?

A: Our perforated tubes offer excellent corrosion resistance, robust durability, precision finishes, and high adaptability, supporting efficient filtration and controlled airflow. Their customizable nature ensures optimized performance for specialized industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

SS Wire Mesh Circle

Shape : Round

Technique : Woven

Process : Punching

Surface Treatment : Other , Polished

Material : Stainless Steel

Application : Filtration, Sieving, Industrial, Chemical, Food Processing

Screen Filter equipment

Shape : Cylindrical or basketshaped (as per design requirement)

Technique : Other, Perforated/Woven mesh fabrication, advanced welding

Process : Screen mesh insertion and highpressure molding

Surface Treatment : Other , Polished, Powder coated, Anticorrosive coating

Material : Other , Stainless steel, Polypropylene (PP)

Application : Irrigation systems, industrial water filtration, agriculture, water treatment plants

Industrial Screen Guard Filter

Shape : Cylindrical, Round, or Customizable

Technique : Other, Welded Mesh / Perforated

Process : Punching, Welding, Finishing

Surface Treatment : Other , Polished / Galvanized

Material : Stainless Steel

Application : Industrial Filtration, Water Treatment, Chemical Processing

Guard Filter Equipment

Shape : Cylindrical

Technique : Other, Welded and perforated

Process : Cutting, shaping, welding, polishing

Surface Treatment : Other , Polished, anticorrosive coated

Material : Stainless Steel

Application : Industrial filtration systems, water treatment plants, chemical processing, oil & gas industries, power plants

Send Inquiry

Send Inquiry