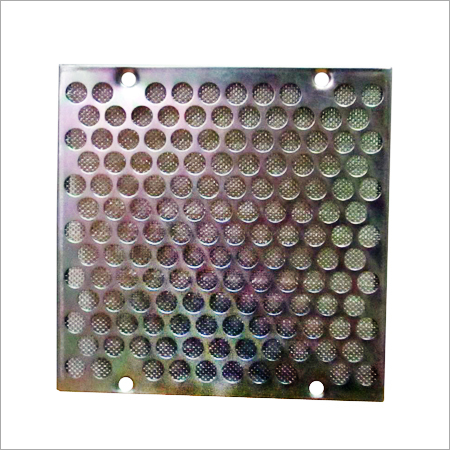

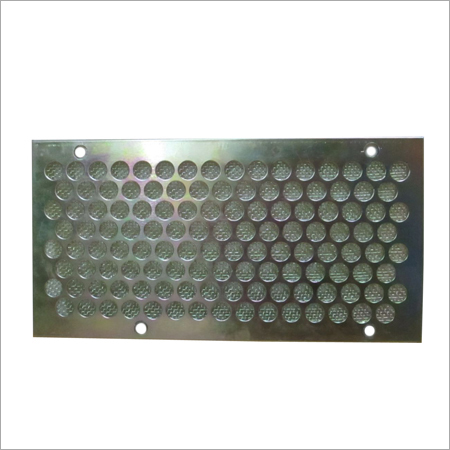

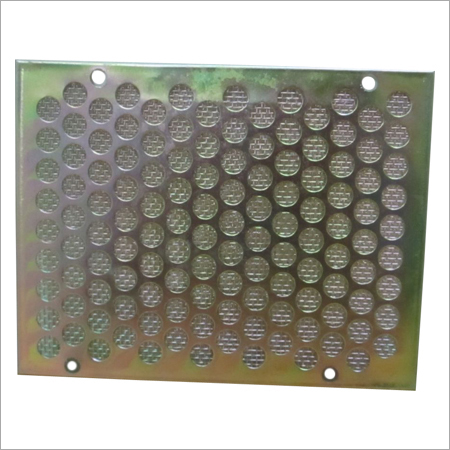

Perforated Tube filter

Perforated Tube filter Specification

- Temper

- As per customer requirement

- Shape

- Cylindrical, Round

- Process

- Punching, Forming, Fabrication

- Standard

- ASTM, DIN, ISO

- Surface Treatment

- Polished, Galvanized, Coated

- Material

- Stainless Steel, Mild Steel, Galvanized Steel

- Type

- Perforated Tube Filter

- Technique

- Perforation, Welding, Rolling

- Thickness

- 0.5 mm to 3 mm (customizable)

- Application

- Liquid Filtration, Air Filtration, Industrial Filters, Water Treatment Plants

- Feature

- Corrosion Resistance, High Durability, Fine Filtration, High Strength

- Pressure Rating

- Up to 10 Bar

- Certificates

- ISO 9001:2015, CE

- Diameter

- 20 mm to 500 mm

- End Caps

- Flat, Flanged, Custom

- Hole Pattern

- Round, Square, Slotted

- Packing

- Poly bags, Carton box, Wooden case

- Hole Size

- 0.5 mm to 10 mm

- Operating Temperature

- -50°C to 300°C

- Length

- 100 mm to 2000 mm

- Customization

- Available as per client drawing

- Installation

- Weldable, Clampable, Threaded

- Open Area Ratio

- Adjustable 5% - 60%

About Perforated Tube filter

To establish a prominent presence in the market, we are engaged in manufacturing and supplying Perforated Tube Filter. To manufacture this filter, we use premium grade stainless steel. The quality inspectors check this filter on sturdiness and durability parameters to provide the defect free range to clients. We can customize this Perforated Tube Filter in different sizes and specification as per client's requirements. Also, we offer this filter at pocket friendly prices.

Features:

- Easy to clean

- Resistant to corrosion

- Breakage free

Wide-Ranging Customization Options

Tailor the Perforated Tube Filter to your precise needs, choosing from multiple materials like stainless steel, mild steel, or galvanized steel. Adjust hole size, pattern, length, and open area to suit diverse industrial filtration applications. End caps can be flat, flanged, or custom-designed, with installation methods including welding, clamping, or threading.

Built for Durability and High Performance

Designed to withstand extreme temperatures and pressures, this filter offers high corrosion resistance and structural integrity. The robust fabrication process and quality certifications ensure longevity and reliability in both air and liquid filtration environments, making it ideal for challenging settings such as water treatment and industrial plants.

Certified Quality and Flexible Packaging

Each Perforated Tube Filter is manufactured to meet stringent industry standards like ASTM, DIN, and ISO, ensuring consistent, reliable performance. Packaging options range from poly bags to wooden cases, safely delivering your filter wherever needed. This, combined with available custom fabrication, makes it an excellent choice for global suppliers and manufacturers.

FAQs of Perforated Tube filter:

Q: How do I select the appropriate perforated tube filter for my application?

A: Begin by identifying the required hole size (0.5 mm to 10 mm), hole pattern (round, square, or slotted), diameter (20 mm to 500 mm), and length (100 mm to 2000 mm) that match your filtration needs. Consider the operating temperature, pressure rating, and desired open area ratio. Our team can assist in customizing the filter to your exact specifications.Q: What materials are available for the perforated tube filter, and how do I determine the best choice?

A: The filter is available in stainless steel, mild steel, galvanized steel, and other materials upon request. Material selection should be based on the fluid or gas being filtered, environmental conditions, and required corrosion resistance. Stainless steel is preferred for high durability, while mild steel or galvanized options offer cost-effective solutions for less demanding scenarios.Q: When is it necessary to request a custom design for the filter?

A: A custom design is recommended if your project requires non-standard dimensions, unique end caps, special surface treatments, or tailored open area percentages. If you have a detailed drawing or specific industry requirements, these can be accommodated to optimize the filters performance within your system.Q: Where can these filters be installed, and which industries benefit most?

A: Perforated tube filters are suitable for installation in industrial settings such as water treatment plants, air filtration systems, and various manufacturing processes. They can be installed using welding, clamping, or threaded connections, providing flexibility for integration in existing or new setups.Q: What is the manufacturing process for the perforated tube filter?

A: The process includes punching holes (perforation), forming the tube shape, welding joints, and fabricating end caps. Surface treatments like polishing, galvanizing, or coating are applied based on application requirements. Each filter is crafted according to global standards and can be produced as per customer drawings.Q: How do these filters enhance system performance and longevity?

A: With features like fine filtration, high strength, and corrosion resistance, these filters protect downstream equipment from contaminants, reduce maintenance frequency, and enhance overall system reliability. Their adjustable open area allows precise control over filtration capacity and efficiency.Q: What packaging and certification assurances come with each filter?

A: Filters are securely packed in poly bags, carton boxes, or wooden cases depending on shipping needs. Each product is delivered with certifications like ISO 9001:2015 and CE, confirming compliance with rigorous quality standards for peace of mind in global industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

Screen Filter equipment

Material : Other , Stainless steel, Polypropylene (PP)

Temper : Annealed or as required

Technique : Other, Perforated/Woven mesh fabrication, advanced welding

Application : Irrigation systems, industrial water filtration, agriculture, water treatment plants

Process : Screen mesh insertion and highpressure molding

Thickness : Standard: 1.2 mm 3 mm (can be customized)

Industrial Screen Guard Filter

Material : Stainless Steel

Temper : Hard

Technique : Other, Welded Mesh / Perforated

Application : Industrial Filtration, Water Treatment, Chemical Processing

Process : Punching, Welding, Finishing

Thickness : 0.8 mm 2 mm

Perforated Tube

Material : Other , Stainless Steel, Mild Steel, Aluminium

Temper : Customizable

Technique : Other, Perforation, Welded

Application : Filtration, Exhaust Pipes, Oil and Gas, Agriculture, HVAC

Process : Cold Rolled, Hot Rolled

Thickness : 0.5 mm to 3 mm

Screen Guard Filter

Material : Other , Polycarbonate

Temper : Normal

Technique : Other, Precision Cut

Application : Computer Monitor, Laptop Display, LCD/LED Screen

Process : Laser Cutting

Thickness : 0.3 mm

Send Inquiry

Send Inquiry