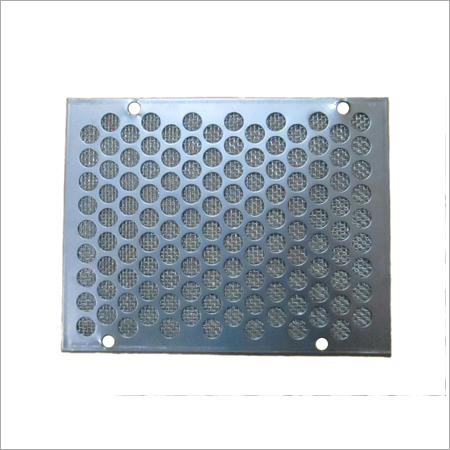

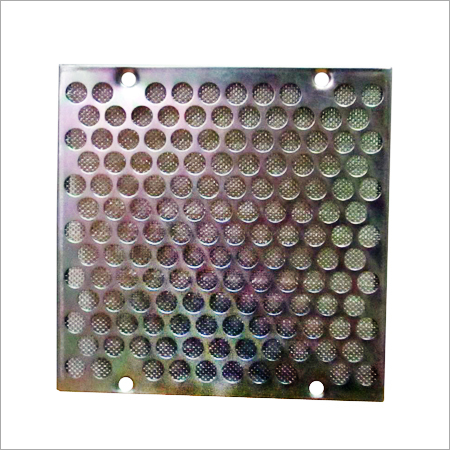

Screen Filter equipment

Screen Filter equipment Specification

- Shape

- Cylindrical or basket-shaped (as per design requirement)

- Surface Treatment

- Polished, Powder coated, Anti-corrosive coating

- Standard

- ISO 9001:2015, CE Certified

- Process

- Screen mesh insertion and high-pressure molding

- Temper

- Annealed or as required

- Material

- Stainless steel, Polypropylene (PP)

- Type

- Screen Filter equipment

- Technique

- Perforated/Woven mesh fabrication, advanced welding

- Thickness

- Standard: 1.2 mm - 3 mm (can be customized)

- Application

- Irrigation systems, industrial water filtration, agriculture, water treatment plants

- Feature

- Efficient filtration, easy cleaning, corrosion resistant, high durability

- Mounting Method

- Inline, Flanged

- Flow Rate Capacity

- 3-50 m3/hr

- Filtration Rating

- 100-120 mesh

- Color

- Black/Blue

- Operating Temperature Range

- 5°C to 60°C

- Inlet/Outlet Size

- 1 inch (25 mm) to 4 inch (100 mm)

- Maximum Pressure

- 10 Bar (145 PSI)

- Cleaning Method

- Manual & Semi-Automatic

About Screen Filter equipment

Our company has succeeded to achieve respectable position in the market as a reputed manufacturer and supplier of Screen Filter Equipment. This equipment is manufactured under the firm guidance of expert supervisors using high quality stainless steel. Highly demanded in the market, this filter comes in different sizes and finishing. We check this Screen Filter Equipment on defined quality parameters to provide the defect free range to clients. Also, we offer this filter at reasonable prices.

Features:

- Light weight

- Sturdy in nature

- Resistant to corrosion

Robust Construction & Versatile Material Options

Choose between stainless steel or polypropylene (PP) construction to suit your application needs. Each filter is available with various surface treatments such as polished, powder-coated, or anti-corrosive coatings, ensuring long-lasting durability even under demanding conditions. Advanced welding and precise screen mesh insertion offer consistent performance.

Efficiency in Filtration and Easy Maintenance

The 100-120 mesh filtration provides effective removal of debris and particulate matter, safeguarding downstream equipment and improving water quality. Designed for either manual or semi-automatic cleaning, these filters allow for minimal downtime and easy upkeep.

FAQs of Screen Filter equipment:

Q: How does the Screen Filter equipment ensure efficient filtration?

A: The filter utilizes a fine 100-120 mesh screen fabricated using perforated or woven mesh techniques, which captures a wide range of particulates. This ensures that the system delivers clean water for irrigation, industry, or agriculture.Q: What is the cleaning process for this filter, and how often should it be done?

A: Cleaning can be performed manually or semi-automatically, depending on operational preferences. The frequency depends on the contamination level of your input water but should be carried out whenever a significant reduction in flow rate is noticed or per the maintenance schedule.Q: When and where can this filter be installed?

A: This inline, flanged filter is suitable for installation in irrigation systems, industrial water filtration, agricultural pipelines, or water treatment plants. It can operate optimally within a temperature range of 5C to 60C and manage a pressure of up to 10 Bar.Q: What are the main benefits of choosing this screen filter for your application?

A: Key benefits include high filtration efficiency, corrosion resistance, extended durability, and easy maintenance. Its robust design ensures reliable operation, minimizing system downtime and protecting auxiliary equipment.Q: How does the construction process contribute to the filters reliability?

A: Each filter is constructed using advanced welding and high-pressure molding for inserting the screen mesh. Surface treatments like anti-corrosive coating and powder coating further augment its lifespan, making it suitable for rigorous environments.Q: What customization options are available for this filter?

A: Thickness can be customized from 1.2 mm to 3 mm as per project requirements, and the filter can be supplied in cylindrical or basket-shaped designs to meet specific installation needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in perforated tubes Category

Perforated Tube

Process : Cold Rolled, Hot Rolled

Temper : Customizable

Type : Perforated Tube

Standard : ASTM, DIN, ISO

Material : Other , Stainless Steel, Mild Steel, Aluminium

Shape : Round

Guard Filter Equipment

Process : Cutting, shaping, welding, polishing

Temper : Customizable as per requirement

Type : Guard Filter Equipment

Standard : IS/ASTM/DIN/EN

Material : Stainless Steel

Shape : Cylindrical

Perforated Filter

Process : Mechanical Perforation, Laser Cutting

Temper : Annealed, Hardened

Type : Perforated Filter

Standard : ASTM, DIN, ISO

Material : Other , Stainless Steel, Mild Steel, Aluminum

Shape : Round, Rectangular, Custom shapes

Perforated Tube filter

Process : Punching, Forming, Fabrication

Temper : As per customer requirement

Type : Perforated Tube Filter

Standard : ASTM, DIN, ISO

Material : Other , Stainless Steel, Mild Steel, Galvanized Steel

Shape : Cylindrical, Round

Send Inquiry

Send Inquiry